BLOG

What is cellulose sponge and what is the use of cellulose sponge?

Posted by admin in Product Information Tags: cellulose sponge, compressed cellulose sponge on May 9, 2019

We have adequate inventory of the cellulose sponge. Small quantity order/wholesale, custom made with specific dimension or shape is available.

Cellulose sponge, is made of 100% biodegradable natural wood pulp, cotton and hemp fibres.

Cellulose sponge is an international new cleaning material, green and environmentally friendly, replacing the original PU sponge, PVA sponge and other cleaning materials containing pollution, used in printing plate making, food and beverage industry, electronic assembly industry, photography industry, beauty body Industry, metal anti-rust industry, clean room operation, moisturizing packaging industry, medical industry, safety assembly industry, automobile industry, ceramic industry, construction industry, leakproof packaging industry, air compressor dehumidification, stadium emergency drying, etc. . Moreover, with the gradual enhancement of people’s environmental awareness and the gradual improvement of living standards, cellulose sponge has been widely used in many fields around the world.

Featrues of cellulose sponge.

- Strong and flexible, tough, not easy to break, extremely durable

- No chemical fiber, pure wood pulp fiber hydrophilic and oil-repellent, rich in self-cleaning, strong water absorption and decontamination.

- Wash and knead after use, harden after drying to prevent bacteria from growing, and quickly return to soft after water.

- Compressible, the cellulose sponge can be compressed to the paper-thin, easy to store and carry, and after touching water, it can rapidly restore to the same thickness before compression.

Main use of cellulose sponge.

- Beauty use: cellulose sponge is an ideal skin care product, use the sponge to gently wipe the face to thoroughly cleanse the face. Long-term use can eliminate blackheads.

- Bath use: Apply a little amount of body lotion to the surface of the cellulose sponge to produce a rich foam, clean and thoroughly cleansed.

- Car wash: Use the cellulose sponge to wipe the body to completely remove dirt, no damage to the car body, windows, no scratches, and no water marks.

- Kitchen use: The cellulose sponge can be used to wash kitchen utensils, ceramics, glass products, etc..It is extremely absorbent, flexible, washable, solvent resistant, non-sticky, easy to air dry, etc. It is a durable and environmentally friendly cleaning product.

- Industrial use: especially for electric soldering iron and mechanical equipment, the cellulose sponge suitable for surface cleaning of industrial agriculture and machinery, it can completely remove dirt and grease, especially suitable for soldering iron and cleaning printing equipment.

2019 Chinese New Year Holiday Notification

Posted by admin in Company News on January 28, 2019

Dear valued customers,

Happy 2019 Chinese New Year – Year of the Pig.

Master Sponge will have the CNY holidays from 30th Jan 2019 until 15th Feb 2019.

During the holiday, you are still free to contact with us for any inquiry.

And all the orders will be processed and dispatched after 15th Feb 2019.

Thanks for your support and understanding.

Best regards,

Master Sponge Sales Team

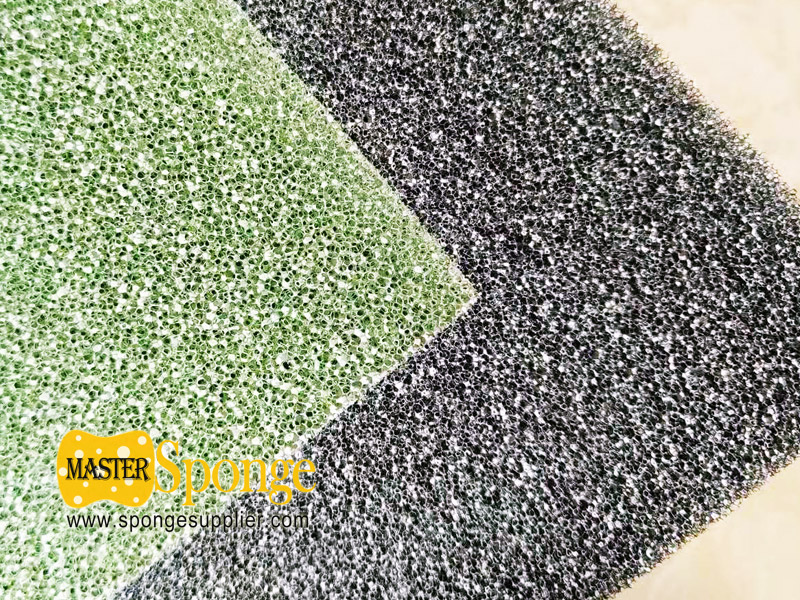

The difference between cold catalyst filter foam and photocatalyst filter foam.

Posted by admin in Product Information on October 15, 2018

Nowadays, the technology of air purifiers has been relatively mature. Currently, purifiers on the market generally use activated carbon nets, HEPA filters, negative ions, electrostatic dust collection, photocatalysts and cold catalyst technology.

So, what’s the difference between cold catalyst and photocatalyst?

The cold catalyst also known as low temperature catalyst, formaldehyde buster. It is another new type of purification material after the photocatalyst air purification material.

Cold catalyst is a low-temperature and low-adsorption catalyst. It catalyzes the decomposition of organic compounds in the air with oxygen to produce water and other substances that are harmless to the human body, thereby achieving the elimination of harmful bacteria and carcinogenicity of organic compound at normal temperature.

The photocatalyst absorbs the organic compound in the air through the catalyst when the air conditioner inhales. After the adsorption concentration is full, it must be irradiated by ultraviolet rays or dried in the sun for a certain time, so that the adsorbent becomes water and carbon dioxide, and the photocatalyst can restore the adsorption function. In general, there is no big difference between the two, but the work process is different.

Compared with cold catalysts, photocatalysts are also an effective way to solve harmful gas pollution. However, unlike cold catalysts, photocatalysts require adsorbent materials to adsorb and decompose harmful gases. As the use time increases, the efficiency will decrease. Therefore, after using for a period of time, it needs to be exposed to strong sunlight, so that the harmful gas contained in the adsorbent material is decomposed and volatilized. If the exposure is insufficient or not timely, not only the photocatalyst can no longer decompose harmful gases, but also due to harmful substances in the adsorbent materials. The gas volatilizes and causes secondary pollution, and the adsorbed particle suspension can even become a breeding ground derived from bacteria.

Therefore, from the perspective of safety, the cold catalyst seems to be safer.

What’s the difference between ACF(activated carbon fiber), GAC(granular activated carbon) and PAC(powdered activated carbon)?

Posted by admin in Product Information on September 3, 2018

Activated Carbon Fiber (ACF), Granular Activated Carbon (GAC) and Powdered Carbon (PAC) are basically carbon materials with massive open pores, but there are differences in the structure of the pores and amount of radicals.

The distribution of the pore diameters in ACF concentrate under 20 angstroms with surface area ranging from 1000 m2/g to 1500 m2/g. Whereas the pore diameters in GAC and PAC could distribute from 20 to several hundred angstroms. And their surface areas are only about 800 m2/g to 1000 m2/g. VAN DER WAALS interactions are the major source of adsorption. However, due to its long and slit pore structure, ACF has the capillary attraction that does not exists in GAC and PAC hence performs much faster adsorption than GAC and PAC by several hundred times. With only a few exceptions in hi-tech areas, ACF has not been adopted as prevailing as GAC and PAC in the industries owing to its high cost. In fact, by putting together all of the advantages of ACF with regard to its fast adsorption/desorption speed, decomposition temperature as high as 500 degree centigrade, less land-occupation, easy handling and remarkable regeneration frequency, the integral economic efficiency of ACF is actually much higher than that of GAC and PAC.

a. The pore structure of Activated Carbon Fiber (ACF) and Granular Activated Carbon (GAC)

b. The interaction energy on the surface of activated carbon

(a) the mutual attraction energy at a single carbon surface can only reach out very little beyond the surface and the adsorption power is nothing significant.

(b) wider pores can be taken as the result of partial overlapping of two single carbons drawn by the attraction power. The attraction power then multiplies due to the accumulation of energy.

(c) when two pores are coming to perfect overlapping at a narrow hole, the maximum energy of two pores are then added together resulting in the significantly increase of the attraction power.

c. Comparison of pores distribution between ACF and GAC

A majority of pore distribution in ACF is micropores which are of much less Diameter and more concentration

A Comparison of pores distribution between ACF and GAC

For information about activated carbon reticulated filter foam products, please visit:

http://www.spongesupplier.com/product-category/filter-sponge/activated-carbon-filter-foam/

PRODUCT INTRODUCTION: HOW TO STAY COOL ON THE RUN DURING MARATHON RACE?

Posted by admin in Product Information on April 28, 2018

Some of the marathon races held on hot season, it’s easy to overheat during the race and to suffer heat stroke, expecially running on the Southeast Asian countries.

I always use the marathon cooling sponges which can grab on each aid station/gel and sponge station to keep cooling.

Except squeezing the sponge on the head directly to let the ice water flow through your skin. There is a better way to keep you cooling, just remember to grab a few couple of ice cubes while you taking the sponge from the station, put the ice cubes on the top of the sports sponge, then put your hat on over both…as the ice cubes will melt into the sponge, it create a cool spot on your head and a nice trickle of water running down your neck.

You can also use your running headband or outdoor headscarf to bind up with the sponge, our cooling sponge can hold 25ml-30ml water at minimum, then you can squeez it in several times to let the water to cool your body down slowly.

We have several colors of the marathon sponge/sports sponge available, and they have been already tested on many races.

We can also custom make the shape and color of the sponge according to your requirment, just feel free to contact us and ask for a quote.

2018 Chinese New Year Holiday Notification

Posted by admin in Company News on February 6, 2018

HAPPY CHINESE NEW YEAR – YEAR OF THE DOG –

Dear valued customers,

Master Sponge will celebrate 2018 Chinese Spring Festival from 7th Feb 2018 until 25th Feb 2018.

During the holiday, you are free to place orders or contact with us for any inquiry.

All the orders will be processed and dispatched on 26th Feb 2018.

Thanks for your support and undertanding.

Best regards,

Master Sponge Sales Team

National Day Holiday Announcement

Posted by admin in Company News on September 27, 2017Dear Customer,

We would like to inform that our company will be offed for National Day Holiday from 1st to 8th October,2017.

We will be resuming on 9th October,2017.

Sample making, order picking and shipping will be NOT avialable during holiday.

But inquiry will still available during holiday to provide you with any assistance or information you want.

Thank you for your support and understanding in advance.

Master Sponge & Foam Products Manufacturer

FAQ: IS MY INFORMATION CONFIDENTIAL?

Posted by admin in Uncategorized on May 15, 2017Yes, we at Master Sponge & Foam Products Manufacturer provide the signed NDA(Non-Disclosure Agreement) document and maintain the confidentiality of our clients.

So don’t worry about security of information.

Announcing the launch of our new website

Posted by admin in Company News on March 5, 2017Master Sponge is proud to announce the launch of our new website which coincides with our expanding role as a reliable sponge and foam products supplier and provide professional project solution for the industry.

Our new website provides a clear message of who we are, what is our advantage and we can do. The website also boasts a clean design and intuitive and consistent site-wide navigation system with improved menu functionality that directs you to the information most relevant to you. It is also fully responsive with mobile devices, making it easy to navigate on a wide range of web browsers and portable devices.

We’ve launched a range of new product category to the website, including CELLULOSE SPONGE, RUBBER SPONGE, MAKEUP SPONGE and etc…

In addition, our BLOG will not only post our company news but also share sponge, foam and relevant industry information and product knowledge.

We also plan to continue adding more video content and product information to provide you with all of the information you need to evaluate our products and services.

We’re really proud of the new website and feel it will create the experience you’re looking for when you pay us a visit.

For any suggestion and question, please feel free to contact us at any time.

Holiday Notice of Spring Festival (2017 Chinese New Year)

Posted by admin in Company News on January 5, 2017

Dear Valued Customers:

We would like take this opportunity to thanks for your long term support in 2016 Year!

Due to the Chinese Spring Festival Holiday coming, our office will be temporarily out of working from 25/1/2017 to 6/2/2017.

If the order is placed after 10th Jan. 2017, the delivery time should be delayed after the holiday. (the final date, please confirm with our sales representative)

If any urgent order or assistance in need ,please feel free to contact us before our holiday, we will try to support in advance.

During the holiday, the email may not reply timely, if there is anything urgent thing, please contact Jerry which his mobile is +86-132-6896-3440 and email is jerry@spongesupplier.com.

We are sorry for all the inconvenience may caused, and thanks again for your kindly understanding and support.

Best Regards,

Master Sponge

- « Previous

- 1

- 2

- 3

- Next »