Archives

What’s different between Polyurethane foam, Polyether foam and Polyester foam?

Posted by admin in Product Information on July 18, 2021Polyurethane(PU) foam mainly includes polyester foam and polyether foam, which can be sliced or rolled, and can also be processed by composite processing, hot pressing and blasting for open-cell structure according to customer requirements. PU foam is involved in various industries, including automobile industry, battery industry, cosmetics industry, bust underwear manufacturing industry, and furniture manufacturing industry due to its heat preservation, heat insulation, sound absorption, shock absorption, flame retardant, anti-static, and good air permeability.

Polyether foam has better water resistance, antibacterial resistance and low temperature impact resistance than Polyester foam, so polyether foam is ideal for aquarium and water treatment.

Polyester foam: In addition to the properties of polyether foam, it also has special properties such as oil resistance, abrasion resistance, corrosion resistance, high temperature resistance, and strong stretchability, and the product has uniform cells, good gloss, and composite adhesion to the fabric. Strong knot rate and other characteristics, widely used in high-end vehicle interiors, high-end fabric composite, flocking, cosmetics, printer consumables, filtration, and other fields. There is a simpler way to distinguish Polyether foam and Polyester foam: stretch the foam until it breaks. The polyester requires a lot more force and the elongation is greater than 150%.

| COMPARISION BETWEEN POLYETHER AND POLYESTER | |

| Hydrolytic resistance | polyether > polyester |

| Elastic resilience | polyether > polyester |

| Low temperature impact resistance | polyether > polyester |

| Moisture evaporation | polyether > polyester |

| Bacteria resistance | polyether > polyester |

| Tensile strength | polyether < polyester |

| Tear strength | polyether < polyester |

| Attrition resistance | polyether < polyester |

| Drug resistance | polyether < polyester |

| Transparency | polyether < polyester |

Open-cell PU reticulated filter foam 10 PPI – 60 PPI

Posted by admin in Product Information on May 28, 2021Open-cell Reticulated Filter Foam is made of polyurethane(PU) foam, with through-hole structure as the base material. It has better aerodynamic performance, small volume density, large specific surface area, high adsorption efficiency, and wind resistance. The coefficient is small. It can be widely used in the treatment of benzene, toluene, xylene and other organic gases, phenols, esters, alcohols, aldehydes and other organic gases and malodorous gases, and various gases with low concentration and large air volume containing trace heavy metals. The exhaust gas can be directly discharged after adsorption, concentration and purification.

Specifications and parameters:

Product features: easy to adjust the pore size, good air permeability, and can be cut arbitrarily.

Conventional size: up to 120*200 (㎝).

Conventional thickness: 3-800 (mm).

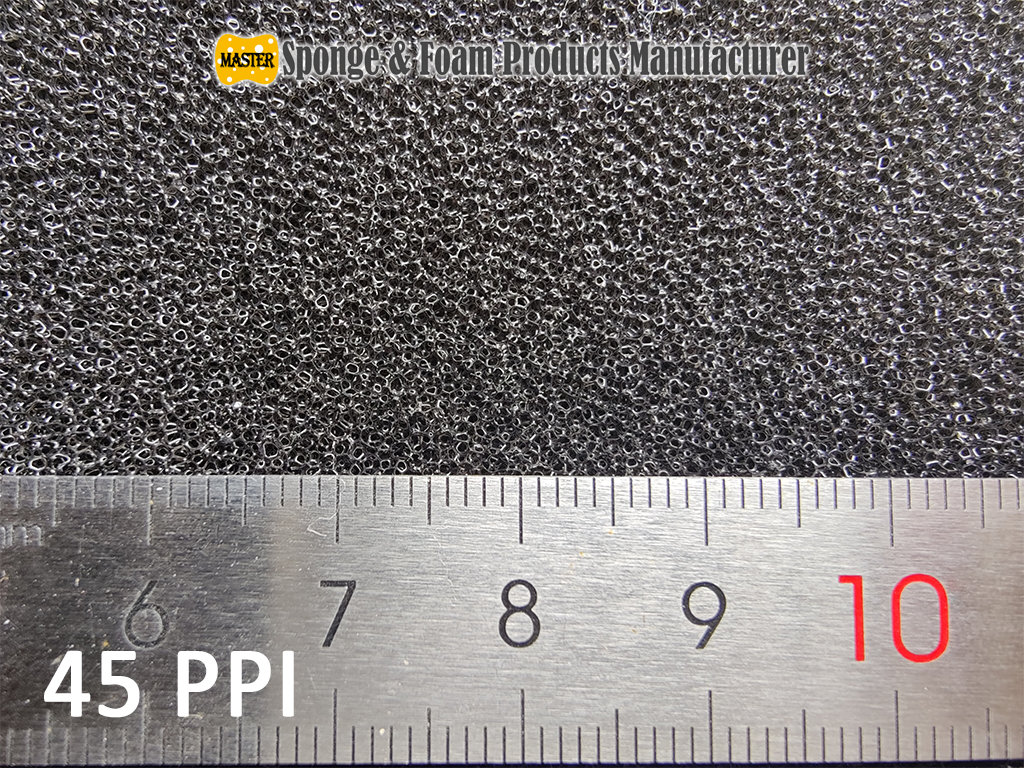

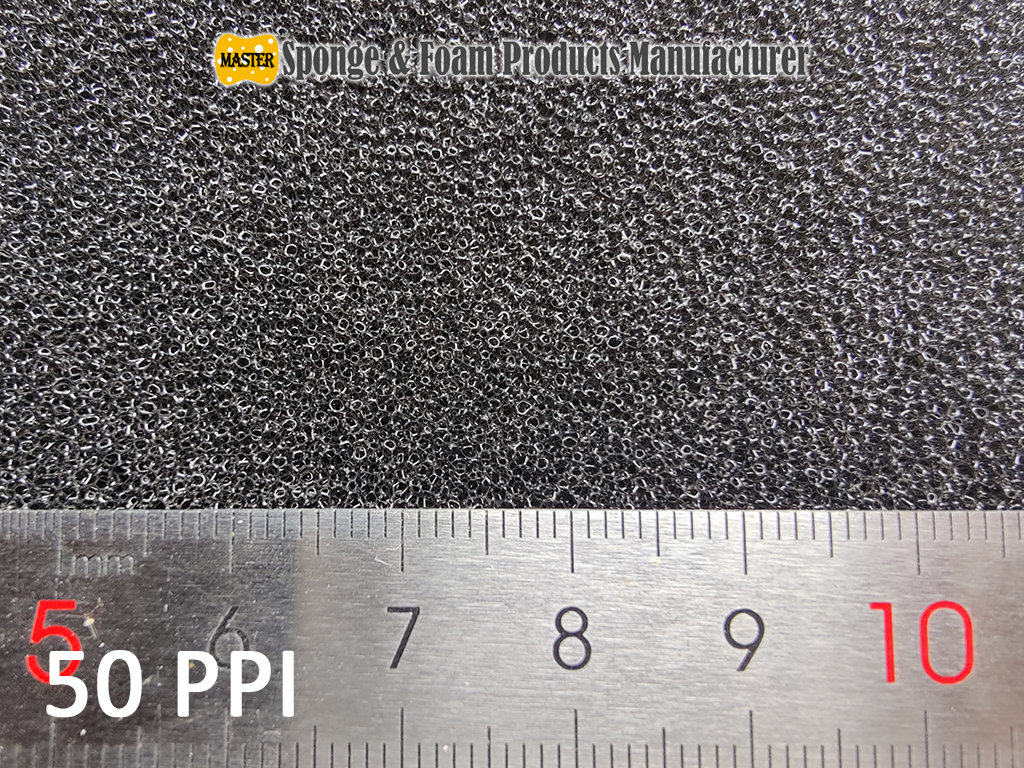

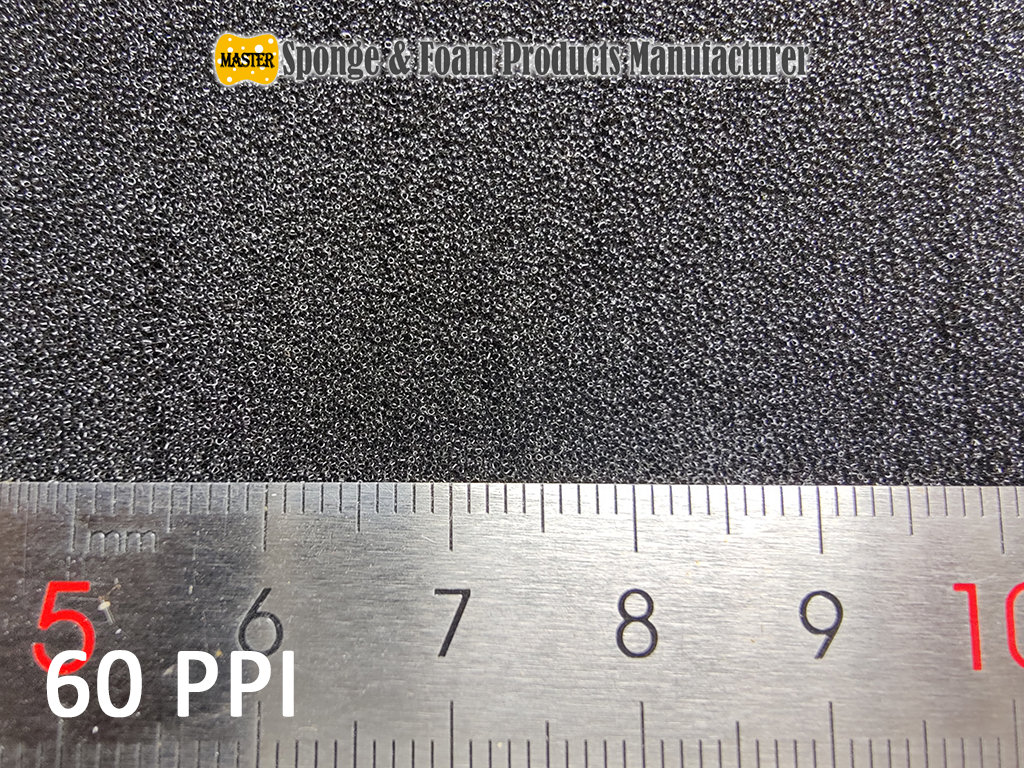

Common pore diameters: fine pores (45-80 PPI), medium pores (25-40 PPI), large pores (10-20 PPI)

Wind resistance: The gas linear velocity is 1.0 m/s, and the pressure drop is ≤42Pa (tested with a 4 mm thick mesoporous filter material.

Product performance:

(1) High opening rate

(2) Good air permeability

(4) Permanent flexibility

(5) Harmless to the human body, no pollution to the environment, no smell

(6) Water resistance, strong drainage after immersion

(7) Recyclable, it is easy to destroy, and there is no secondary pollution to the environment

Application:

Mainly used in the filter layer of air conditioners and air filters of vehicles, aquarium filters, heat-resistant porous mesh ceramics fired with mesh sponges, nickel alloy meshes sintered after electroplating, which can be used as metallurgy Industry filter materials and other uses.

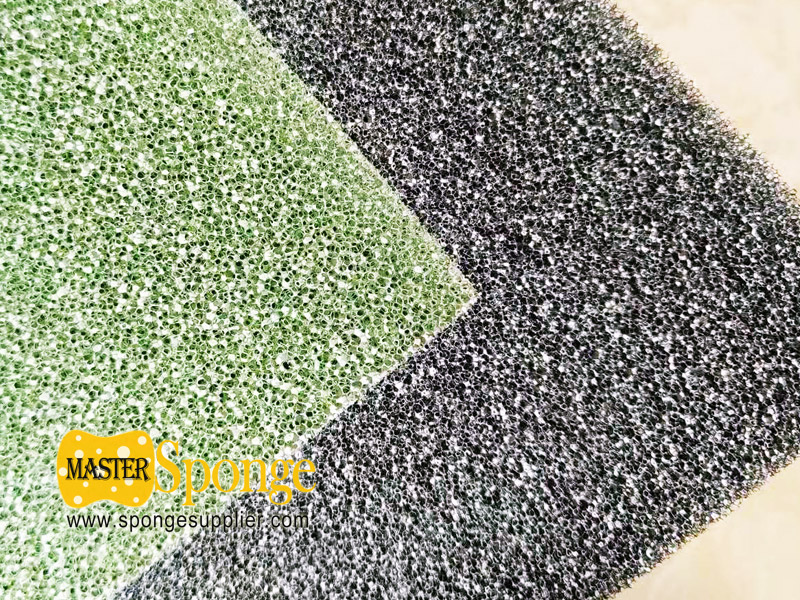

Photos of 10 PPI – 60 PPI foam:

Wholesale Product: Compressed Dehydrated Cellulose Sponge(Facial Sponge)

Posted by admin in Product Information Tags: cellulose sponge, compressed cellulose sponge on April 28, 2021

We have adequate inventory of the cellulose sponge. Small quantity order/wholesale, custom made with specific dimension or shape is available.

The following item is available for wholesale, please feel free to send inquiry if you are interests in it.

| ITEM NAME | Compressed dehydrated cellulose sponge(Faical Sponge) |

| DIMENSIONS | Φ65 x 1mm, expanding thickness when hydrated: 8-10 mm |

| PACKAGING | 50 pcs in one sealed polybag |

| WEIGHT | approx. 60g one bag |

| MOQ | 5,000 pcs |

How many wavelengths of light can illuminate the photocatalyst material to get the best environmental purification effect?

Posted by admin in Product Information on July 21, 2020

Photocatalyst reticulated filter foam

Photocatalyst is a general term for photo-semiconductor materials with photocatalytic function represented by nano-sized titanium dioxide. It is currently one of the materials used to control indoor environmental pollution in the world.

Under the irradiation of light, the photocatalyst will produce a photocatalytic reaction similar to photosynthesis, and produce free hydroxyl groups and active oxygen with strong oxidizing ability. It has a strong photo-redox function and can oxidize and decompose various organic compounds and parts. Inorganic substances can destroy the cell membranes of bacteria and the proteins that solidify viruses, kill bacteria and decompose organic pollutants, and decompose organic pollutants into pollution-free water (H2O) and carbon dioxide (CO2), thus having a strong sterilization, Deodorization, anti-mildew, anti-fouling, self-cleaning, and air purification functions.

In order to get the best photocatalytic effect, the wavelength of the UV-light should be less than 380nm.

Currently the most used is 254nm(commonly used ultraviolet lamp) or 365nm.

Because the shorter the wavelength, the stronger the energy, but the smaller the radiation range.

So in the large space, the 365nm will has the better effect than 254nm.

But in the small space, the 254nm will has the better effect than 365nm.

Master Sponge and Foam Products Manufacturer produce Photocatalyst Reticulated Filter Foam, which widely used in air conditioners, air purifiers, car purification systems, air purification in factories/workshops and other products.

Can the Reticulated PU Foam and the Activated Carbon Sponge filter the air?

Posted by admin in Product Information on October 20, 2019Regular Reticulated PU Sponge Filters are used in air purification to remove some large particles of pet dander and hair.

In practical applications, air filter manufacturers will use activated carbon to impregnate them, while filtering large particles, they can also remove volatile organic compounds such as TVOC, odor, formaldehyde and other harmful substances. It is popular as an initial filter in air purifiers and fresh air systems.

We call it Activated Carbon Sponge Filter.

Activated Carbon Sponge Filter

Activated Carbon Sponge Filter can be used to remove volatile organic compounds and related pollutants such as large particles, odor, formaldehyde, voc, etc. in the air during air purification.

Honeycomb activated carbon sponges are often impregnated with activated carbon. Its carbon content is about 30-50%, and it has good adsorption performance.

Commonly used in air purifiers, home air conditioners, central air conditioners, air fresheners, range hoods, heaters, air conditioning fans, and special purpose duct filtration.

Product Features:

1. Adsorption performance: Benzene adsorption capacity: > 90%; Iodine adsorption capacity: 1000mg/g or more

2. Deodorization performance: 30 minutes for ethanethiol removal rate ≥ 90%; Trimethylamine removal rate ≥ 90%

3. Operating temperature range: -20 °C ~ 130 °C

Product specifications: thickness 3-25mm

So can the Activated Carbon Sponge Filter be washed?

Which performance is better than HEPA high efficiency filters?

Master Sponge and Foam Products Manufacturer tell you: Activated Carbon Sponge Filter is easy to deform after washing, the pore size will be enlarged, it is not recommended to wash. It can be replaced every 3 months. This layer of sponge filter acts as the first filter of the air filtration system. It can block some large particles for the HEPA filter high-efficiency filter in the back, reduce the burden of HEPA filter, and extend the life of the high efficiency filter relatively.

Obviously, Activated Carbon Sponge Filters have lower filtration performance for 0.3 micron microparticles than HEPA filters. The particle size of the particles filtered by the two is different. The HEPA filter has a higher filtration accuracy. The sponge filter has low resistance when purifying the air, but it cannot block the fine dust in the strong air flow. The HEPA filter is mainly made of high-efficiency filter paper, which can block more than 99.9% of the fine particles.

Classification Of Activated Carbon

Posted by admin in Product Information on June 20, 2019

Activated carbon filter foam is one of our major products.

Activated carbon plays an important role in the industrial field and in daily life. Activated carbon is an excellent carbon adsorbent with a large specific surface area, stable physical and chemical properties, and good selective adsorption properties.

What are differences between types of activated carbon? How are they classified?

1. Classified by raw materials:

| CATEGORY | RAW MATERIALS |

| Coal-based activated carbon | Lignite, peat, bituminous coal, anthracite and etc… |

| Wooden activated carbon | Sawdust, charcoal, coconut shell, walnut shell, apricot shell and etc… |

| Petroleum activated carbon | Asphalt, petroleum coke |

| Regeneration carbon | Used charcoal |

2. Classified by appearance:

| CATEGORY | CHARACTERISTIC |

| Powdered activated carbon(PAC) | Powdery, mesh<80 |

| Granular activated carbon(GAC) | Granular, mesh>80 |

| Spherical activated carbon(SAC) | Ball shaped carbide being activated after carbonization, and raw material of a spherical resin also belongs to this class |

| Columnar activated carbon(CAC) | Using coal, wood chips and etc as raw materials, the appearance is cylindrical |

| Fibrous activated carbon(FAC) | Made of fibrous raw materials, diameter is 5-10μm. Generally felt, cloth, filament |

| Honeycomb activated carbon(HAC) | Produce by extrusion process |

3. Classified by different activation methods:

| CATEGORY | CHARACTERISTIC |

| Physical activated carbon | Produced by using water vapor, CO2, flue gas, air as activator |

| Chemical activated carbon | Produced by using chemicals such as zinc chloride, phosphoric acid, sodium hydroxide or potassium hydroxide as activators |

| Physical and Chemical activated carbon | Produced by using chemicals and certain gases sequentially or simultaneously |

We can produce activated carbon filter foam with different iodine value base on different types of the activated carbon as your requirement.

What is cellulose sponge and what is the use of cellulose sponge?

Posted by admin in Product Information Tags: cellulose sponge, compressed cellulose sponge on May 9, 2019

We have adequate inventory of the cellulose sponge. Small quantity order/wholesale, custom made with specific dimension or shape is available.

Cellulose sponge, is made of 100% biodegradable natural wood pulp, cotton and hemp fibres.

Cellulose sponge is an international new cleaning material, green and environmentally friendly, replacing the original PU sponge, PVA sponge and other cleaning materials containing pollution, used in printing plate making, food and beverage industry, electronic assembly industry, photography industry, beauty body Industry, metal anti-rust industry, clean room operation, moisturizing packaging industry, medical industry, safety assembly industry, automobile industry, ceramic industry, construction industry, leakproof packaging industry, air compressor dehumidification, stadium emergency drying, etc. . Moreover, with the gradual enhancement of people’s environmental awareness and the gradual improvement of living standards, cellulose sponge has been widely used in many fields around the world.

Featrues of cellulose sponge.

- Strong and flexible, tough, not easy to break, extremely durable

- No chemical fiber, pure wood pulp fiber hydrophilic and oil-repellent, rich in self-cleaning, strong water absorption and decontamination.

- Wash and knead after use, harden after drying to prevent bacteria from growing, and quickly return to soft after water.

- Compressible, the cellulose sponge can be compressed to the paper-thin, easy to store and carry, and after touching water, it can rapidly restore to the same thickness before compression.

Main use of cellulose sponge.

- Beauty use: cellulose sponge is an ideal skin care product, use the sponge to gently wipe the face to thoroughly cleanse the face. Long-term use can eliminate blackheads.

- Bath use: Apply a little amount of body lotion to the surface of the cellulose sponge to produce a rich foam, clean and thoroughly cleansed.

- Car wash: Use the cellulose sponge to wipe the body to completely remove dirt, no damage to the car body, windows, no scratches, and no water marks.

- Kitchen use: The cellulose sponge can be used to wash kitchen utensils, ceramics, glass products, etc..It is extremely absorbent, flexible, washable, solvent resistant, non-sticky, easy to air dry, etc. It is a durable and environmentally friendly cleaning product.

- Industrial use: especially for electric soldering iron and mechanical equipment, the cellulose sponge suitable for surface cleaning of industrial agriculture and machinery, it can completely remove dirt and grease, especially suitable for soldering iron and cleaning printing equipment.

The difference between cold catalyst filter foam and photocatalyst filter foam.

Posted by admin in Product Information on October 15, 2018

Nowadays, the technology of air purifiers has been relatively mature. Currently, purifiers on the market generally use activated carbon nets, HEPA filters, negative ions, electrostatic dust collection, photocatalysts and cold catalyst technology.

So, what’s the difference between cold catalyst and photocatalyst?

The cold catalyst also known as low temperature catalyst, formaldehyde buster. It is another new type of purification material after the photocatalyst air purification material.

Cold catalyst is a low-temperature and low-adsorption catalyst. It catalyzes the decomposition of organic compounds in the air with oxygen to produce water and other substances that are harmless to the human body, thereby achieving the elimination of harmful bacteria and carcinogenicity of organic compound at normal temperature.

The photocatalyst absorbs the organic compound in the air through the catalyst when the air conditioner inhales. After the adsorption concentration is full, it must be irradiated by ultraviolet rays or dried in the sun for a certain time, so that the adsorbent becomes water and carbon dioxide, and the photocatalyst can restore the adsorption function. In general, there is no big difference between the two, but the work process is different.

Compared with cold catalysts, photocatalysts are also an effective way to solve harmful gas pollution. However, unlike cold catalysts, photocatalysts require adsorbent materials to adsorb and decompose harmful gases. As the use time increases, the efficiency will decrease. Therefore, after using for a period of time, it needs to be exposed to strong sunlight, so that the harmful gas contained in the adsorbent material is decomposed and volatilized. If the exposure is insufficient or not timely, not only the photocatalyst can no longer decompose harmful gases, but also due to harmful substances in the adsorbent materials. The gas volatilizes and causes secondary pollution, and the adsorbed particle suspension can even become a breeding ground derived from bacteria.

Therefore, from the perspective of safety, the cold catalyst seems to be safer.

What’s the difference between ACF(activated carbon fiber), GAC(granular activated carbon) and PAC(powdered activated carbon)?

Posted by admin in Product Information on September 3, 2018

Activated Carbon Fiber (ACF), Granular Activated Carbon (GAC) and Powdered Carbon (PAC) are basically carbon materials with massive open pores, but there are differences in the structure of the pores and amount of radicals.

The distribution of the pore diameters in ACF concentrate under 20 angstroms with surface area ranging from 1000 m2/g to 1500 m2/g. Whereas the pore diameters in GAC and PAC could distribute from 20 to several hundred angstroms. And their surface areas are only about 800 m2/g to 1000 m2/g. VAN DER WAALS interactions are the major source of adsorption. However, due to its long and slit pore structure, ACF has the capillary attraction that does not exists in GAC and PAC hence performs much faster adsorption than GAC and PAC by several hundred times. With only a few exceptions in hi-tech areas, ACF has not been adopted as prevailing as GAC and PAC in the industries owing to its high cost. In fact, by putting together all of the advantages of ACF with regard to its fast adsorption/desorption speed, decomposition temperature as high as 500 degree centigrade, less land-occupation, easy handling and remarkable regeneration frequency, the integral economic efficiency of ACF is actually much higher than that of GAC and PAC.

a. The pore structure of Activated Carbon Fiber (ACF) and Granular Activated Carbon (GAC)

b. The interaction energy on the surface of activated carbon

(a) the mutual attraction energy at a single carbon surface can only reach out very little beyond the surface and the adsorption power is nothing significant.

(b) wider pores can be taken as the result of partial overlapping of two single carbons drawn by the attraction power. The attraction power then multiplies due to the accumulation of energy.

(c) when two pores are coming to perfect overlapping at a narrow hole, the maximum energy of two pores are then added together resulting in the significantly increase of the attraction power.

c. Comparison of pores distribution between ACF and GAC

A majority of pore distribution in ACF is micropores which are of much less Diameter and more concentration

A Comparison of pores distribution between ACF and GAC

For information about activated carbon reticulated filter foam products, please visit:

http://www.spongesupplier.com/product-category/filter-sponge/activated-carbon-filter-foam/

PRODUCT INTRODUCTION: HOW TO STAY COOL ON THE RUN DURING MARATHON RACE?

Posted by admin in Product Information on April 28, 2018

Some of the marathon races held on hot season, it’s easy to overheat during the race and to suffer heat stroke, expecially running on the Southeast Asian countries.

I always use the marathon cooling sponges which can grab on each aid station/gel and sponge station to keep cooling.

Except squeezing the sponge on the head directly to let the ice water flow through your skin. There is a better way to keep you cooling, just remember to grab a few couple of ice cubes while you taking the sponge from the station, put the ice cubes on the top of the sports sponge, then put your hat on over both…as the ice cubes will melt into the sponge, it create a cool spot on your head and a nice trickle of water running down your neck.

You can also use your running headband or outdoor headscarf to bind up with the sponge, our cooling sponge can hold 25ml-30ml water at minimum, then you can squeez it in several times to let the water to cool your body down slowly.

We have several colors of the marathon sponge/sports sponge available, and they have been already tested on many races.

We can also custom make the shape and color of the sponge according to your requirment, just feel free to contact us and ask for a quote.