Daily Archives: October 15, 2018

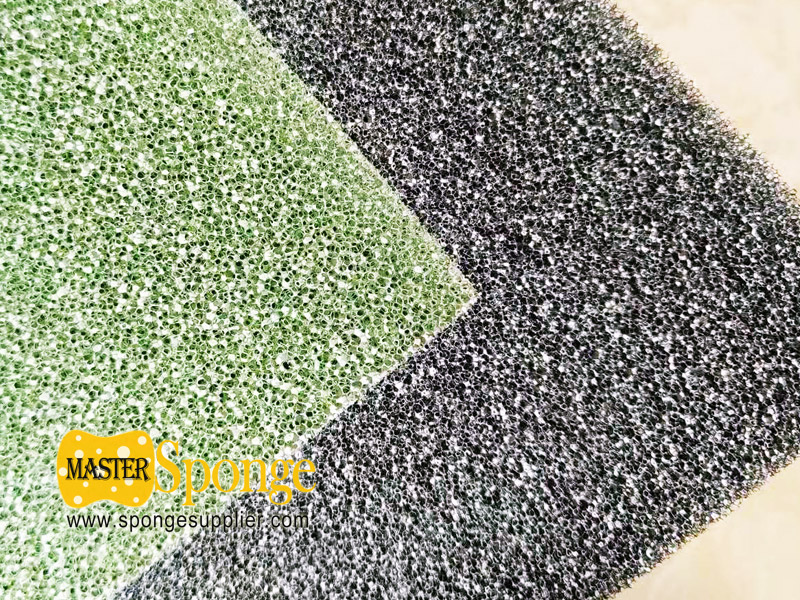

The difference between cold catalyst filter foam and photocatalyst filter foam.

Posted by admin in Product Information on October 15, 2018

Nowadays, the technology of air purifiers has been relatively mature. Currently, purifiers on the market generally use activated carbon nets, HEPA filters, negative ions, electrostatic dust collection, photocatalysts and cold catalyst technology.

So, what’s the difference between cold catalyst and photocatalyst?

The cold catalyst also known as low temperature catalyst, formaldehyde buster. It is another new type of purification material after the photocatalyst air purification material.

Cold catalyst is a low-temperature and low-adsorption catalyst. It catalyzes the decomposition of organic compounds in the air with oxygen to produce water and other substances that are harmless to the human body, thereby achieving the elimination of harmful bacteria and carcinogenicity of organic compound at normal temperature.

The photocatalyst absorbs the organic compound in the air through the catalyst when the air conditioner inhales. After the adsorption concentration is full, it must be irradiated by ultraviolet rays or dried in the sun for a certain time, so that the adsorbent becomes water and carbon dioxide, and the photocatalyst can restore the adsorption function. In general, there is no big difference between the two, but the work process is different.

Compared with cold catalysts, photocatalysts are also an effective way to solve harmful gas pollution. However, unlike cold catalysts, photocatalysts require adsorbent materials to adsorb and decompose harmful gases. As the use time increases, the efficiency will decrease. Therefore, after using for a period of time, it needs to be exposed to strong sunlight, so that the harmful gas contained in the adsorbent material is decomposed and volatilized. If the exposure is insufficient or not timely, not only the photocatalyst can no longer decompose harmful gases, but also due to harmful substances in the adsorbent materials. The gas volatilizes and causes secondary pollution, and the adsorbed particle suspension can even become a breeding ground derived from bacteria.

Therefore, from the perspective of safety, the cold catalyst seems to be safer.