CLASSIFICATION OF ACTIVATED CARBON

Product Information on June 20, 2019

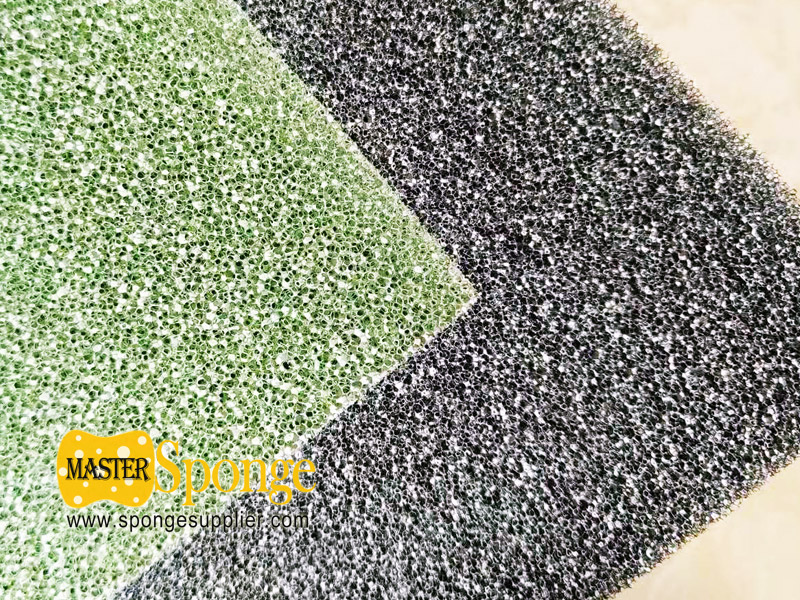

Activated carbon filter foam is one of our major products.

Activated carbon plays an important role in the industrial field and in daily life. Activated carbon is an excellent carbon adsorbent with a large specific surface area, stable physical and chemical properties, and good selective adsorption properties.

What are differences between types of activated carbon? How are they classified?

WHAT IS CELLULOSE SPONGE AND WHAT IS THE USE OF CELLULOSE SPONGE?

Product Information Tags: cellulose sponge, compressed cellulose sponge on May 9, 2019

We have adequate inventory of the cellulose sponge. Small quantity order/wholesale, custom made with specific dimension or shape is available.Cellulose sponge, is made of 100% biodegradable natural wood pulp, cotton and hemp fibres…

2019 CHINESE NEW YEAR HOLIDAY NOTIFICATION

Company News on January 28, 2019

Master Sponge will have the CNY holidays from 30th Jan 2019 until 15th Feb 2019…

THE DIFFERENCE BETWEEN COLD CATALYST FILTER FOAM AND PHOTOCATALYST FILTER FOAM.

Product Information on October 15, 2018

Nowadays, the technology of air purifiers has been relatively mature. Currently, purifiers on the market generally use activated carbon nets, HEPA filters, negative ions, electrostatic dust collection, photocatalysts and cold catalyst technology. So, what’s the difference between cold catalyst and photocatalyst?…

WHAT’S THE DIFFERENCE BETWEEN ACF(ACTIVATED CARBON FIBER), GAC(GRANULAR ACTIVATED CARBON) AND PAC(POWDERED ACTIVATED CARBON)?

Product Information on September 3, 2018

Activated Carbon Fiber (ACF), Granular Activated Carbon (GAC) and Powdered Carbon (PAC) are basically carbon materials with massive open pores, but there are differences in the structure of the pores and amount of radicals…

PRODUCT INTRODUCTION: HOW TO STAY COOL ON THE RUN DURING MARATHON RACE?

Product Information on April 28, 2018

Some of the marathon races held on hot season, it’s easy to overheat during the race and to suffer heat stroke, expecially running on the Southeast Asian countries…

2018 CHINESE NEW YEAR HOLIDAY NOTIFICATION

Company News on February 6, 2018

Master Sponge will celebrate 2018 Chinese Spring Festival from 7th Feb 2018 until 25th Feb 2018.

NATIONAL DAY HOLIDAY ANNOUNCEMENT

Company News on September 27, 2017

We would like to inform that our company will be offed for National Day Holiday from 1st to 8th October,2017.

We will be resuming on 9th October,2017.

ANNOUNCING THE LAUNCH OF OUR NEW WEBSITE

Master Sponge is proud to announce the launch of our new website which coincides with our expanding role as a reliable sponge and foam products supplier and provide professional project solution for the industry.

HOLIDAY NOTICE OF SPRING FESTIVAL (2017 CHINESE NEW YEAR)

Company News on January 5, 2017

We would like take this opportunity to thanks for your long term support in 2016 Year! Due to the Chinese Spring Festival Holiday coming, our office will be temporarily out of working from 25/1/2017 to 6/2/2017.

COMPARISON OF LATEX AND LATEX FREE(HYDROPHILIC POLYURETHANE) MAKEUP SPONGE

Product Information on April 18, 2015

What are the differences between latex and non latex makeup sponges?