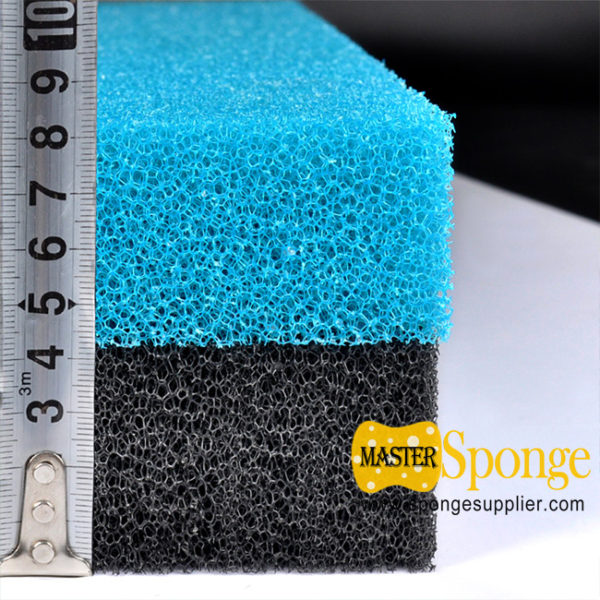

China-made compressible open pore aquatic filtration foam sponge

Product Description :

Filter foam also named reticulation foam,blasting foam.filter foam is made of ordinary open cell through net processing.Opening ratio of filter reaches to 90%~98%, it’s very suitable for filteration with permeability, well flexibility, well machanical strength.

Application :

Industrial waste water treatment, water pollution control, mechanical filtration and pre-filtration of air and water. Although ideal for water filtration, polyether filter foams are also suitable for humidifiers, ventilation systems and acoustic foam for loudspeakers. These foams can be washed and rinsed for re-use many times.

Specifications:

- Raw material: (PU Foam) polyether or polyester foam

- Porosity: 10~60 PPI

- Other available auxiliary functions: mould preventing, asorbing harmful gases, fire retardant,etc.

- Available shapes: sheet, strip, ball, roller, tube, other customized shapes

| RETICULATED FOAM RAW MATERIAL CONSTITUENT | ||

| Polyether/Polyester Glycol | PPG | Water |

| Toluene Diisocyanate | TDI | Colorant |

| Tertiary Amine Compound | AMINE | Tin Catalyst |

| Foam Stabilizer | Olefin Oxide-Polyorganosiloxane | - |

| Grade | Density (kg/m3) | Cell count (cells/cm) | Pore size (pores/inch) | Maximum Dimensions Of Foam Block |

| 10 PPI | 22 ± 2 | 3~4 | 5~15 | 2000 x 1000 x 800mm |

| 20 PPI | 22 ± 2 | 5~6 | 15~25 | 2000 x 1000 x 800mm |

| 30 PPI | 22 ± 2 | 7~9 | 25~35 | 2000 x 1000 x 800mm |

| 40 PPI | 22 ± 2 | 10~13 | 35~45 | 2000 x 1000 x 800mm |

| 60 PPI | 22 ± 2 | 15~18 | 55~65 | 2000 x 1000 x 800mm |

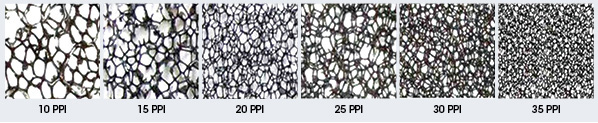

Cell Structure:

Reticulated filter foam operates as a depth-loading filter, as opposed to a surface-loading filter, essentially trapping dust particles within its cells.

The cell structure of filter sponge is remarkable in that each cell has a dodecahedron shape (12 sided), the cell’s walls or “struts” are comprised entirely of organic polymers (polyurethane, polyether, polyester) and the empty space or “windows,” between each strut, comprise 95% – 98% of the filter foam’s mass.

The size, shape & distribution of cells within filter foam can be manipulated during manufacture to provide precisely the desired porosity level, measured in PPI(pores per inch).

10PPI – 35PPI pore densities, approximately full scale

Foam Types and Uses:

Conventional PU foam (padding foam) for padding and packaging – the standard foam. These are available in different densities: A low density foam is suitable for use in making children’s games or leg-rests – one way to look at it is that it is more suitable as a backrests than as a seat cushion. The 35/55 grade is THE standard foam for all padding purposes including reclining cushions and seat cushions. Please note that a foam with a higher density should be used, for instance, in the food services industry, in particular for seat cushions that must withstand heavy use or for overlay materials (cushions) that will have to endure a lot of punishment.

Our range of PU foams can be subdivided into the following categories:

Cold foam is an especially high quality and durable PU foam that is particularly elastic. It is often used for making mattresses or extremely comfortable and high quality seat or bench cushions.

Composite foam is a particularly firm foam. It is easily distinguished from other foams by its mottled appearance. Applications: thin seat cushions, bar stool or motorcycle saddle cushions, acoustic insulation, church kneelers, cushions for ale benches, etc.

Visco elastic foam has a cotton wool kind of consistency, is extremely soft and point elastic. It is especially great for making seat cushions for things like wheel chairs where the time spent sitting will be exceedingly long and comfort is a must. Its primary use, however, is as a mattress topper for increased comfort when sleeping.

Convoluted (egg crate) foam has an unusual three-dimensional surface that is ideal for packaging and acoustic applications.

Filter foam, which is endowed with a special permeability during the production process, is, as a result, used for technical purposes (we carry it primarily as a model making material).

Lighter weight, less firm soft foams tend to be used in greater thicknesses because they are so easy to compress completely, which of course eventually robs them of the padding property. Heavier, firmer foams (for example, composite foam), on the other hand, are usually used in thinner profiles because their greater firmness means you do not need such a thick cushion to achieve comfort. Its greater density, however, means that it will be more expensive.

Subclassification:

Aquatic Filtration, Aquatic Foam, cellular foam, activated carbon filter foam, photocatalyst filter foam, air filter foam, fish tank filters, aquarium filter foam, pond filter foam, pond filter foam, water filter foam, reticulated polyurethane foam, dust filter foam,etc.